Tenron provides higher performance and safety, reduces CO2 impact and is recyclable.

- Wind turbines

- Hydrogen tanks

- Gas tanks

- Battery housings

- Etc.

The Game changer

The best combination of high strength and high impact resistance of any material equals improved design and safety

- Small and very large wind turbine blades

- Latest generation tanks (V)

- Batteries (separators)

Unique resistance in aggressive environments

- Wind turbines in the ocean to withstand a harsh environment (salt water, UV rays, etc.)

- Hydrogen and gas tanks to withstand humidity

- No chemical reaction inside the tank with hydrogen or gas

Resistance to fire (up to 1300 C) increases safety

- Hydrogen tanks

- Gas tanks

- High pressure tanks

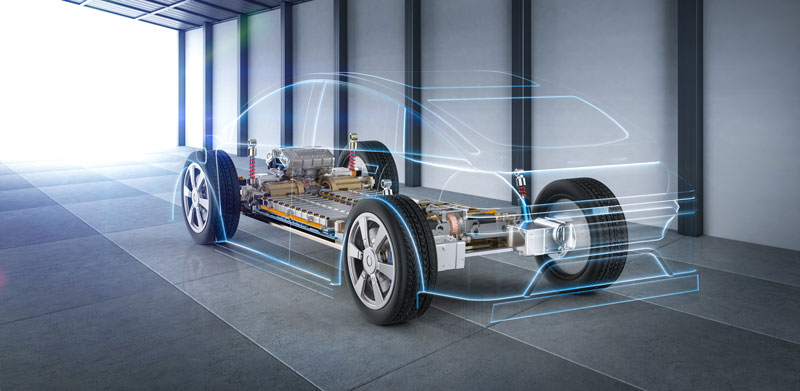

- Battery housings

Excellent weight – strength ratio allows significant reduction of weight

- Wind turbine blades are more easily handled

- Hydrogen tanks to reduce their CO2 impact when being used in transportation

Much longer lifetime compared to other high-performance materials

- High fatigue performance

- High compatibility to any kind of resin

- High resistance to aggressive environments (salt water, UV rays, hydrocarbons, etc.)

- No sensitivity to humidity

Extremely positive environmental impact

- Requires significantly less energy to produce compared to other high-performance materials used today

- The electricity used in the production of Tenron is from 100% certified renewable sources from wind turbines

- Recyclable

- Life cycle assessment (see LCA) extremely interesting compared to other fibres

- Compliant with EU rules on chemical use (REACH)